Click the logo above to be directed to Wilger’s Website

Manifold Flow Indicator Columns

A glance is all it takes to know if the correct amount of liquid is flowing to your spray nozzles or planter openers. When the liquid is flowing equally the balls hover at the same level. A ball that is lower than the others indicates the flow is too low due to a restriction or blockage; a ball that is higher than the others indicates the flow is too high due to a leaking fitting or hose.

• Individual columns clip together so you can gang as many or as few columns as you need.

• Exclusive O-ring seal and joint clip system is easy to assemble and service.

• You can monitor up to three spray tips per column.

• Metering orifices can be inserted to control flows.

• Clear design allows for easy cleaning and troubleshooting.

The Wilger visual ball flow manifold columns are infinitely stackable, so they can be built into any required configuration.

Manifold Flow Indicators come in three different columns sizes, broken down by recommended flow ranges:

Ultra Low Flow Column: 0.01 – 0.24 us gpm flow rates

Low Flow Column: 0.05 – 0.65 us gpm flow rates

Standard Flow Column: 0.07 – 2.70 us gpm flow rates

Click Here to see how to assemble a flow indicator system

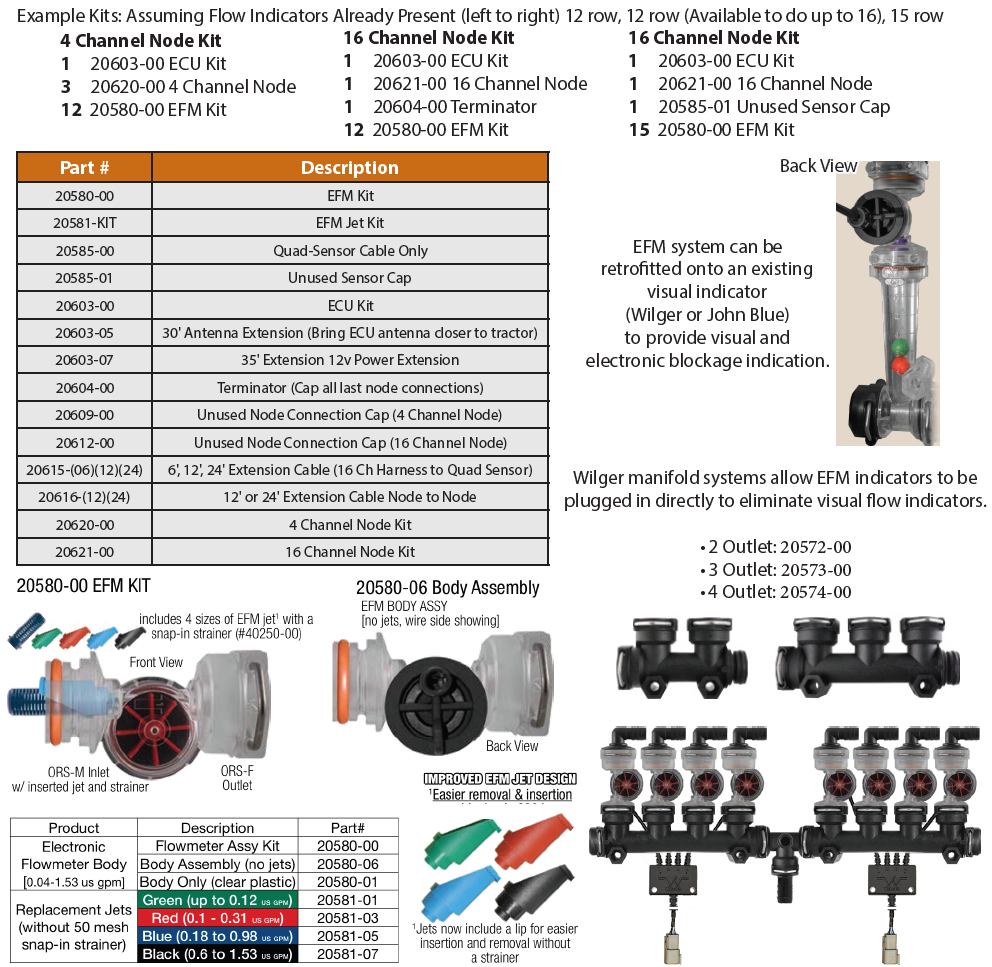

Wilger’s Row-By-Row Flowmeters

The compact flow meter is different than your traditional flow meter in a lot of ways.

Material:

With the TPX polymer body, you get a non-stick surface, excellent chemical resistance, and a clear body that you can use to visually check that the paddle wheel is spinning for any troubleshooting.

Maintenance:

The flowmeters are made and designed by Wilger, ensuring every piece can be serviced and replaced; whereas often flowmeters are virtually impossible or impractical to service or even replace. The only designed part that should wear out and affect accuracy should be the paddle wheel, which can simply be replaced in seconds.

Stabilizing Jets:

The flowmeters have 4 different sizes of stabilizing jets that maintain better accuracy over the operating flow range of the flow meter. The operational ranges below optimize the jet to the application for peak accuracy; however, as long as the jet doesn’t restrict the orifice flow, it can still be as a flow indicator (reduced accuracy).