Ace Pump Corporation has provided pumping solutions for the chemical application, off-highway equipment, air conditioning, and refrigeration markets since 1945.

These varied applications have required Ace to successfully overcome a wide range of engineering challenges.

Ace developed a complete range of products for the agricultural and off-highway equipment markets that do not require the electrical grid for operation.

The pumps are found serving a variety of functions in industry today including: crop sprayers, concrete trucks, asphalt milling machines, anti-icing trucks, turf sprayers, and more.

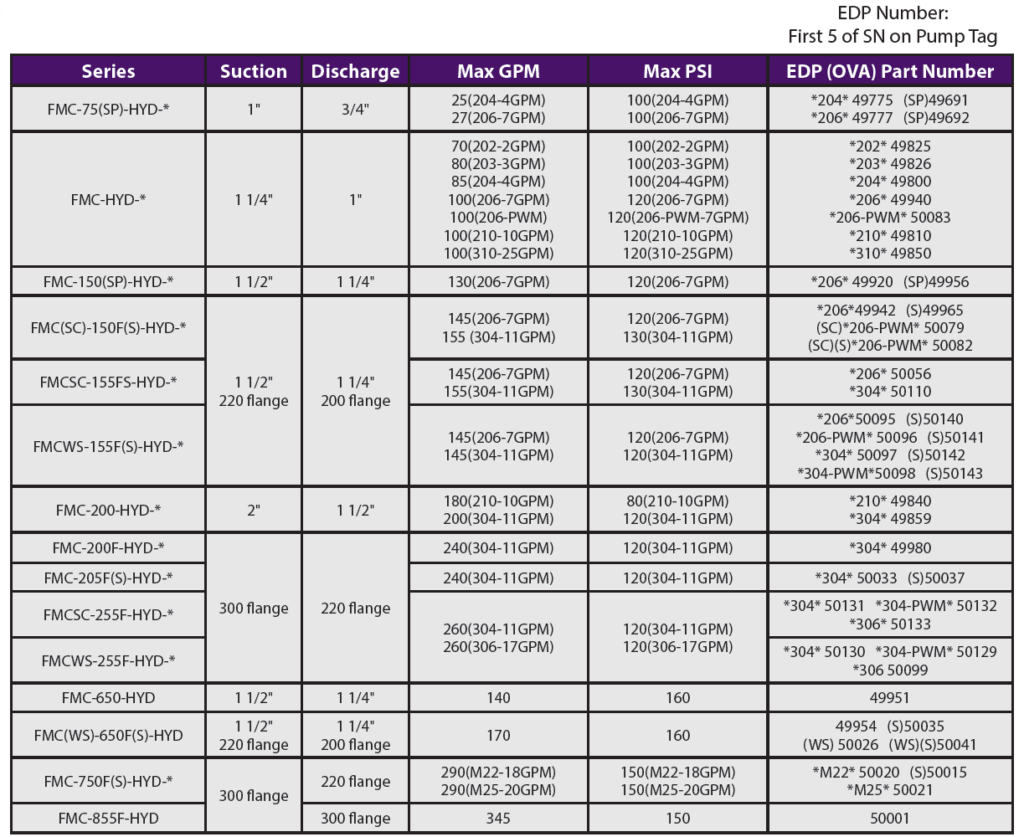

Hydraulic Driven Centrifugal Pumps

Centrifugal pump design provides good resistance to abrasive solutions and extra flow for agitation. All hydraulic driven pumps are equipped with a stainless steel shaft and wear ring for excellent corrosion resistance.

The Ace gear type hydraulic motor is more efficient than gerotor type motors, and is less subject to damage by contamination than the gerotor design. A built-in needle valve allows for the bypass of up to 9 GPM (34 LPM) excess hydraulic fluid on open center systems.

The standard motor has a reverse flow check valve which prevents backward hookup and a coasting check which protects the motor seal from the flywheel effect of the impeller. A restrictor orifice is included with pump models recommended for pressure compensating closed center systems.

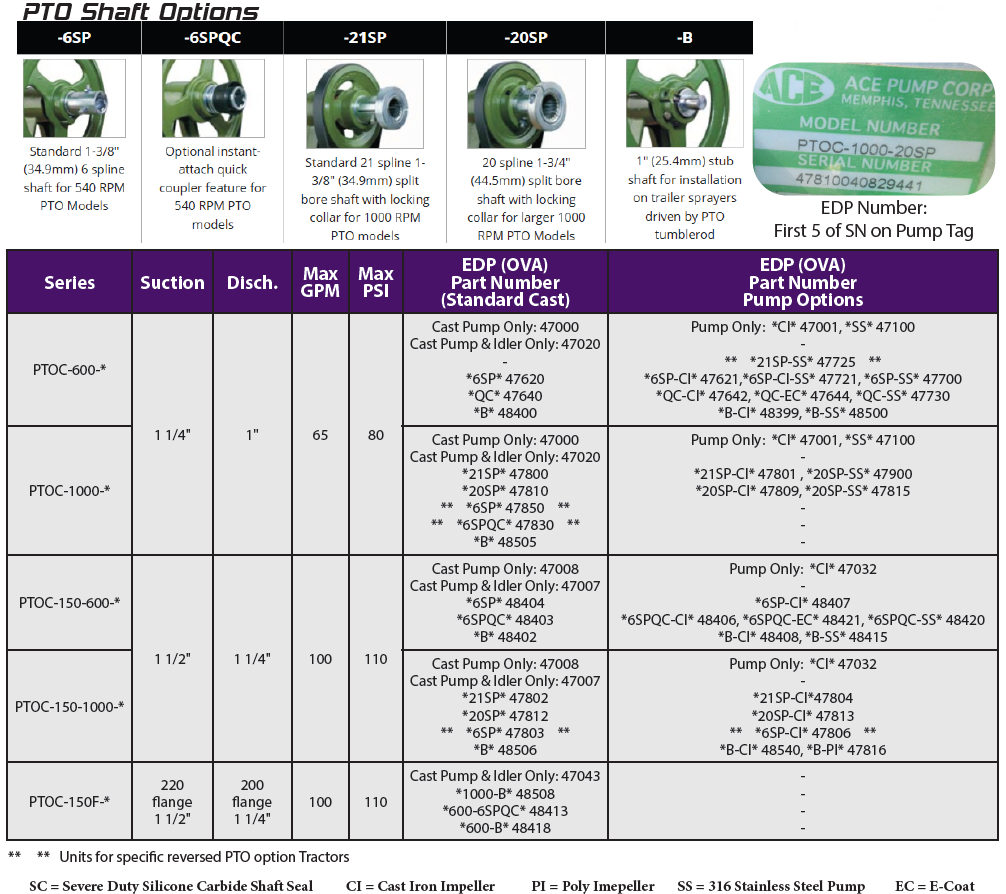

PTO Belt Driven Centrifugal Pumps

The key to success of the Ace belt driven pump has been the Spring Loaded Idler.

The idler maintains proper belt tension which minimizes the load on the pump bearings.

The idler helps absorb the shock of PTO engagement that can destroy cog belts or gears.

Model PTOC belt driven pumps are easy to operate and maintain. Belts can be replaced in the field with minimum downtime and at little cost.

Maintenance features also include sealed ball bearings and a readily replaceable mechanical seal.

The belt guard provides complete coverage of the pulleys, shaft and belt.

All PTO driven Roundup logo pumps are equipped with a stainless steel shaft and wear ring for excellent corrosion resistance

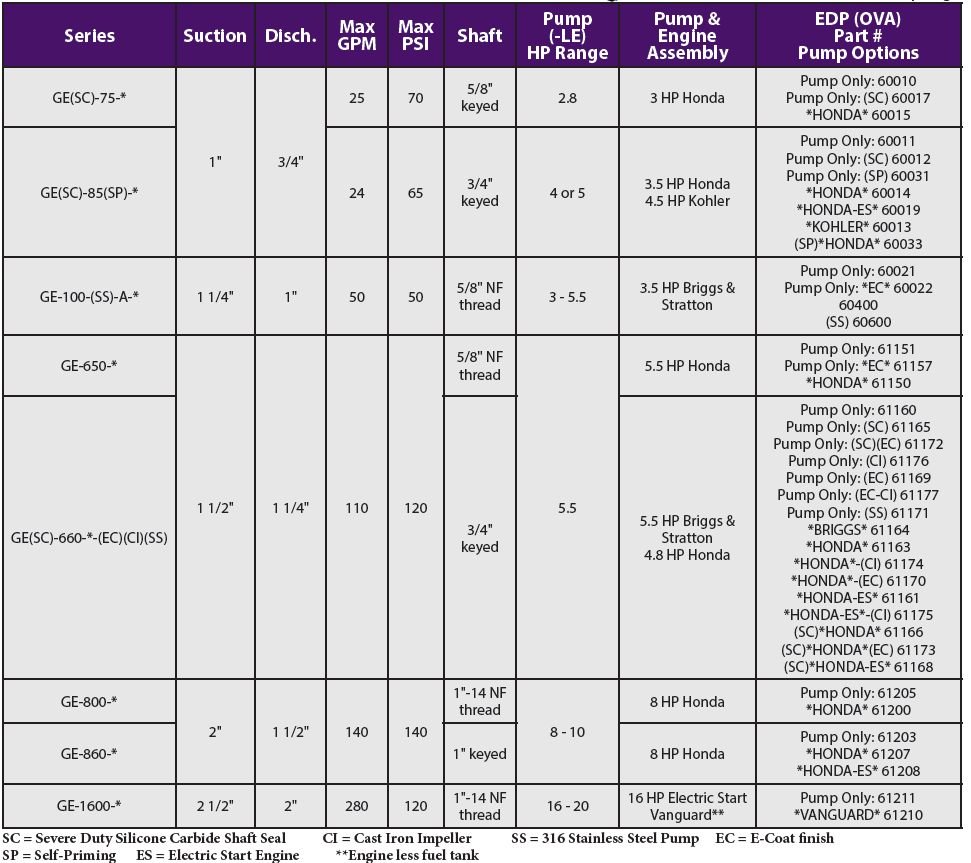

Gasoline Engine Driven Centrifugal Pumps

Ace Pumps offers a complete line of Gasoline Engine Driven Centrifugal Pumps.

These pumps are ideally suited to develop pressure for spray or transfer applications.

The pumps feature a direct couple design with an easily replaceable mechanical seal and slinger ring between pump and engine to prevent liquid from damaging the engine.

Pumps may be purchased complete or less engine (-LE).

Complete units come assembled on the specified engine ready to install and run.

Less engine (-LE) units come with all hardware necessary to mount on the specified engine.

Electric Motor Driven Centrifugal Pumps

For most industrial and agricultural blending, mixing, seed treating and liquid transfer applications.

Easily replaceable Viton® mechanical seal

Non-overloading single phase totally enclosed fan cooled electric motor, for use in all dusty, dirty or weather exposed locations

Optional silicone carbide seal available for abrasive solutions

Chemical resistant Valox® or optional cast iron impeller

| Part (EDP) # | Material | Inlet & Outlet | Max GPM | Max PSI | Motor | Seal |

| MPH-100-50S (32042) | Cast | 1 1/4″ Suction x 1″ Discharge | 60 | 26 | 0.50 HP Single Phase | Dry Seal |

| MPH-100-75S (32046) | Cast | 1 1/4″ Suction x 1″ Discharge | 68 | 32 | 0.75 HP Single Phase | Dry Seal |

| MPH-100-100S (32032) | Cast | 1 1/4″ Suction x 1″ Discharge | 80 | 41 | 1 HP Single Phase | Dry Seal |

Roller Pumps

The Ace Roller Pumps offers a compact, low cost design while ensuring quality construction with a proven design for a large range of spraying, cleaning, and transfer applications.

Standard features include: Cast-Iron construction, Thermoplastic with metal core rollers allow for applying products up to 140°F, FMK lip type seals, Sealed bearings for longer life.

| Part (EDP) # | # of Rollers | GPM | PSI | Max RPM | Shaft Output |

| RP-600C (15050) | 6 | 21.8 | 300 | 1200 | 5/8″ Solid Shaft |

| RP-600PL (15060) | 6 | 21.8 | 300 | 1200 | 5/8″ Solid SS Shaft |

| RP-800C (15000) | 8 | 22.5 | 300 | 1000 | 15/16″ Solid Shaft |

| RP-800PL (15010) | 8 | 22.5 | 300 | 1000 | 15/16″ Solid SS Shaft |